Brief Description

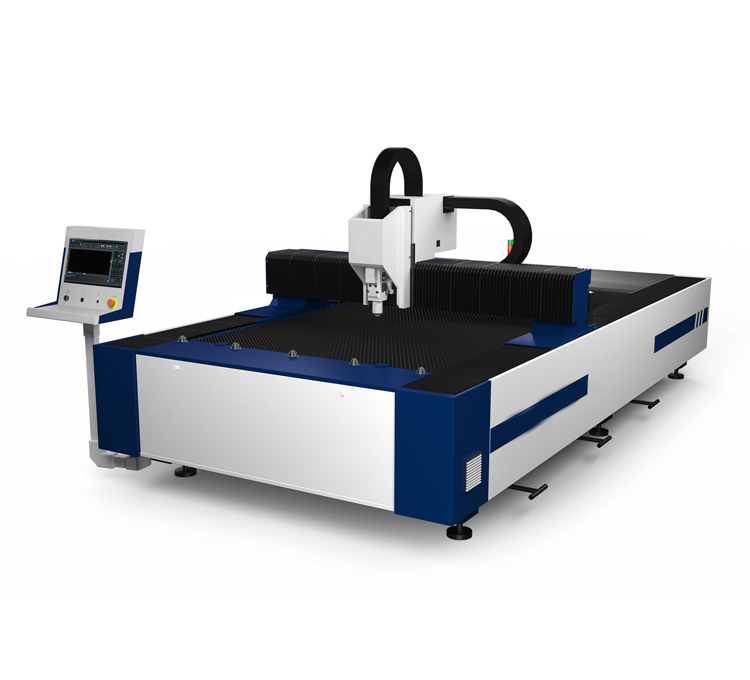

The 3015-D series is one of the flagship products of Salinger laser equipment, mainly used for cutting thick metal plates. It has an open structure, superior performance, stability, and extremely high cost-effectiveness.

Product Features

1、This product adopts a gantry structure, high-quality steel welded bed body, honeycomb shaped high-strength crossbeam, combined with excellent heat treatment and machining technology, to ensure the rigidity of the machine tool and the stability of long-term use.

2、By adopting the DaZu control system, after years of mature use and continuous optimization and improvement in the field of laser cutting, the DaZu control system has achieved high performance, reliability, and user-friendly and convenient operation.

3、The servo motor dual drive precision reducer and gear rack structure ensure high-quality dynamic performance of the equipment.

4、Advanced pneumatic control system design, matched with imported pneumatic components, allows customers to freely use high and low pressure cutting auxiliary gases according to their needs, ensuring cutting quality while effectively reducing usage costs.

Application industry

Various machinery manufacturing and processing industries such as rail transit, shipbuilding, automobiles, engineering machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom, decorative advertising, laser external processing services, etc.

Applicable materials

Various metal materials such as carbon steel, stainless steel, aluminum alloy, brass, copper, pickled plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, etc.

Main Parameter

Item | 3015D | 4020D | 6020D |

Processing area | 3000mm×1500mm | 4000mm×2000mm | 6000mm×2000mm |

X/Y axis location accuracy | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m |

X/Y axis repeat location accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

Max running speed | 120m/min | 100m/min | 100m/min |

Max running acceleration | 1.2g | 1.0g | 1.0g |

Max load of worktable | 700kg | 1200kg | 1800kg |

Power supply | 380V/50HZ | 380V/50HZ | 380V/50HZ |

Machine tool weight | 约4.0T | 约4.5T | 约6.0T |

Dimension(L*W*H) | 5000mm×2300mm×2000mm | 6000mm×2900mm×2000mm | 8500mm×2900mm×2000mm |

Item | 6025D | 8025D |

Processing area | 6000mm×2500mm | 8000mm×2500mm |

X/Y axis location accuracy | ±0.05mm/m | ±0.05mm/m |

X/Y axis repeat location accuracy | ±0.03mm | ±0.03mm |

Max running speed | 100m/min | 100m/min |

Max running acceleration | 1.0g | 1.0g |

Max load of worktable | 3000kg | 4000kg |

Power supply | 380V/50HZ | 380V/50HZ |

Machine tool weight | 约7.5T | 约 9.5T |

Dimension(L*W*H) | 8500mm×3500mm×2000mm | 10500mm×3500mm×2000mm |